Double flow heat pump with energy recovery: HEOLAIR

The HEOLAIR double flow rooftop heat pump is specially designed for ventilation, heating and air conditioning. It ensures fresh air treatment and preparation for any type of premises in low energy buildings. This air handling unit combines an indirect adiabatic cooling system and two counter flow recuperators for maximum energy savings.

Description

The HEOLAIR heat pump is covered by a 20-year anti-corrosion guarantee

The HEOLAIR ventilation and air conditioning solution provides optimum air quality. This double flow rooftop heat pump is delivered ready to operate and can be installed either on a rooftop or at ground level. The design of our heat pumps and the selection of the components used guarantee a high degree of reliability. Thanks to its full aluminium structure (frame & casing), the HEOLAIR unit is covered by a 20-year anti-corrosion guarantee.

The HEOLAIR double flow heat pump with heat recovery operates as a reversible heat pump

- Source: exhaust air

- Treated fluid: hygienic fresh air

The unit offers several operating modes:

- Heating with double energy recovery on exhaust air and high performance heat pump

- Free Cooling economiser mode with exchangers bypass

- Indirect adiabatic cooling without spraying

- "Heatwave" mode with indirect adiabatic cooling, supplemented by the reversible heat pump if necessary

In those cases, this double flow air conditioning unit operates:

- In all fresh air/all exhaust air mode with supply air temperature control

- In all recycled air mode when heating during vacancy periods with return air temperature control

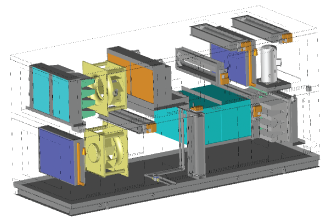

The ETT packaged unit comprises 3 different sections:

- The exhaust air section allows heat recovery and/or removal on exhaust air (depending on the operating mode).

- The separate electrical section houses the electrical board and the control components.

- The supply air section ensures air change and fresh air treatment.

Available options

Frame – Casing

- Motorised external damper on supply air (2006/42/EC Directive)

- Painting

- Porthole

Acoustics

- Compressors acoustic jackets

Air handling

- Magnehelic dial pressure gauge at each filtration stage

- Filters fouling analogue control (FFAC)

- Actuating smoke detector with battery back-up

- Epoxy coating on fans & vinyl coating on exchangers

- Exhaust air fan max. available pressure: 400 Pa

- G4 refillable filters

- 1 set of spare 98 mm G4 filters

- F6 to F9 opacimetric filters, 98 mm thickness in polypropylene without fibreglass Belts protective casing

- Fan guard

Thermodynamics

- HP and LP pressure gauges

- Electronic expansion valves (for On / Off circuit)

Thermal exchangers

- 3-stage electric heater

- Triac

- 2-row hot water coil with analogue frost protection thermostat

- Vinyl coating on hot water coil

- Vinyl coating on direct expansion coils

- Mounted hot water progressive 3-way valve with analogue freezestat

- Mounted stop valve + TA regulating valve on inlet

Electricity

- Unit global energy metering

Control

- Humidity probe (for external humidifier control)

Installation

- 200 or 400 mm aluminium feet