Double flow heat pump: EFFI+ RE

The EFFI+ RE double flow heat pump is specially designed for ventilation, heating and air conditioning in buildings with variable occupancy, such as cinemas, entertainment halls and community halls. This self-contained unit features specific components to maximise energy savings.

As an ErP 2018 ready unit, the EFFI+ RE meets the European regulatory obligations as per Directive 2009/125/EC on the ecodesign of ErPs (Energy related Products).

Description

Double flow rooftop heat pump & air conditioner with rotary heat exchanger covered by a 20-year anti-corrosion guarantee

The ETT packaged unit is delivered ready to operate. Its full aluminium structure (frame & casing) ensures an excellent corrosion protection (20-year anti-corrosion guarantee).

The ETT unit can be installed either at ground level or on a roof. ECODESIGN involves DECONSTRUCTION: ETT units are 98% recyclable (re-use and recycling rates based on ULTI+ 21)

The EFFI+ RE heat pump with heat exchanger operates as a reversible heat pump:

- Source: outside air + exhaust air (in recovery mode)

- Treated fluid: outside air + hygienic fresh air

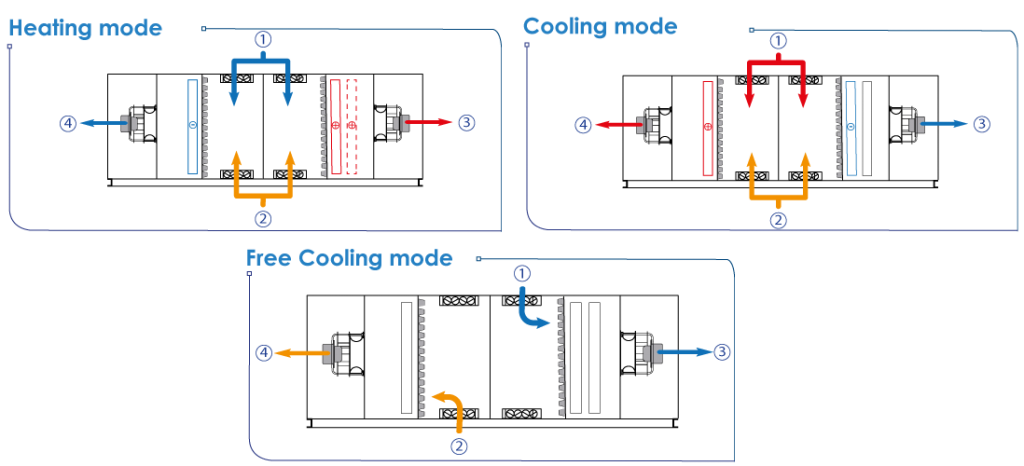

The unit offers several operating modes:

- Heat pump

- Cooling

- Free Cooling: cooling with outside air, without thermodynamics

- Recirculation

The EFFI+ RE offers several operating modes:

![]()

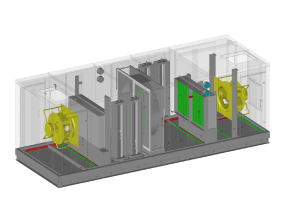

The ETT packaged unit comprises 4 different sections:

- The separate technical section houses the refrigeration components, the electrical board and the control components.

- The internal section ensures air change and air treatment.

- The exhaust air section allows heat recovery and/or removal on exhaust air (depending on the operating mode).

- The rotary heat exchanger section allows heat recovery.

Available options

Frame – Casing

- Motorised external damper on supply air (2006/42/EC Directive)

- Painting

- Delivery in three blocks (sheet metal work assembly, refrigeration assembly and electrical connection shall be done by the customer)

- Whistle shaped cowl for fresh air and exhaust air

Acoustics

- Technical section acoustic insulation using STOPFLAM flexible fire-proof polyurethane foam

- Fresh air cowl acoustic insulation

- Acoustic option

Air handling

- Pressure gauge at each filtration stage

- Analogue air flow controller (AFC), air flow rate indication and measurement

- Filters fouling analogue control (FFAC)

- Actuating smoke detector with battery back-up

- Epoxy coating on fans & vinyl coating on exchangers

- Supply air fan max. available pressure: 600 Pa

- Exhaust air fan max. available pressure: 400 Pa

- Operation with all recirculated air or all fresh air (not available for public access buildings)

- G4 refillable filters

- 1 set of spare 98 mm G4 filters

- 98 mm F6 to F9 opacimetric filters

Thermodynamics

- HP and LP pressure gauges

- Electronic expansion valves

Thermal exchangers

- Sequential electric heater (auxiliary: 2 stages/preheating: 3 stages)

- Triac

- 2-row hot water coil with vinyl coating and analogue frost thermostat

- Mounted progressive 3-way valve hot water

- Mounted stop valve + TA regulating valve on inlet

Installation

- Adjustable aluminium ventilated roof curb

- Adjustable aluminium connection roof curb

- 200 or 400 mm aluminium feet

Electrical

- Unit global energy metering

Control

- Banning of Free Cooling using specific humidity comparison

- Humidity probe (for external humidifier control)

Recovery

- Epoxy protection on rotary heat exchanger

- Humidity probe (for external humidifier control)